Introduction

Eminent Technology was formed in 1982 to manufacture audio products. Audio and sound reproduction is a hobby and passion of the company's founder Bruce Thigpen. The company prides itself in developing products that have a solid foundation in physics and science with high performance at a reasonable price.

At an early age Bruce developed an interest in sound reproduction and electronics. In 1975 he saw an air bearing demonstration in a physics class at a local college. Bruce went to find out who made the air bearings so he could try to build a tonearm with the parts. He found Lew Eckhart in the machine shop and asked about how the parts were made. Lew, an engineer, turned out to enjoy audio as well and had already made a sophisticated air bearing turntable and tonearm. After numerous visits to the lab Bruce convinced Lew to provide him with parts so he could make his own turntable. Lew was very generous, provided parts and taught Bruce tonearm and turntable geometry, machining skills, as well as how to manufacture air bearings. After the turntable was completed Bruce convinced Lew that the turntable Lew had was commercially viable. Lew contacted a number of companies and entered into an agreement to license the turntable design to Infinity and the Infinity Air Bearing turntable was born. The Infinity turntable was manufactured in Japan, a very small number were produced until Infinity was acquired and the project was canceled.

In the Late 1970's, Lew Eckhart introduced the turntable concept to a Tallahassee engineering firm, Wayne H. Coloney Company. Wayne Coloney decided to manufacture the turntable and Bruce Thigpen became the project engineer.

The Colonay AB-1

While working at Coloney Bruce received his first patent on the record vacuum hold down, never used by Coloney, but used later by SOTA in its Star series turntables. When Coloney Filed for chapter 11 bankruptcy in 1982 the turntable Inventory was sold and re branded Mapleknoll. Bruce made a decision to start his own company that same year.

Eminent Technology's first product was an air bearing phonograph tonearm dubbed the Model One. Although utilizing different geometry it was similar to the tonearm used on the Infinity and Coloney AB-1 turntables. In that same year the compact disk player had been introduced and the compact cassette player had already over taken the LP as the best selling prerecorded media. A high end tonearm for playing phonograph records was not something a company could count on for long term success. At the onset, it was apparent that other products would have to be developed.

The Model One Tonearm  |

Tonearm air bearing  |

In order to design a practical air bearing tonearm the air bearing had to be very efficient only requiring a small amount of air to operate. An air bearing is not simply a series of holes which direct air to the surface of a spindle tube. In the case of the Model One or the ET-2 Tonearm air pressure causes a hard coat anodized aluminum spindle to float on a thin layer of air. The air bearing includes a manifold where a pressure cavity provides the air pressure for a series of very small air holes, capillaries, which restrict the flow of air to the surface of the bearing. The spindle floats with a surface pressure less than that on the manifold side of the bearing. If the spindle is canted in the manifold bore the higher pressure in the manifold acts as a centering or restoring force because air cannot rush out of any one capillary with more exposure to the atmosphere.

The ET-2 Tonearm  |

The ET-2 tonearm followed the Model One in 1985. This was a design collaboration between Edison Price and Bruce Thigpen. Edison concentrated on tooling and industrial design, Bruce concentrated on optimizing the geometry of the tonearm. The result was one of the best selling high end tonearms for the next ten years. Bruce received his third patent for a design feature of the ET-2. The ET-2's vertical tracking angle adjustment traveled over and arc to keep the stylus on the center line while adjusting VTA. |

By 1985 The compact disk was gaining traction and the end of the LP phonograph record was thought to be in sight. Bruce had developed both electrostatic and planar magnetic/ribbon loudspeakers so it was decided to concentrate on planar planar magnetic loudspeakers. Magneplanar had been successfully manufacturing single ended planar magnetic loudspeakers for many years. Bruce developed a push pull version of a planar ribbon loudspeaker which made efficient use of magnetic material. His fourth patent, granted in 1987 was for an efficient motor structure used in planar magnetic loudspeakers.

The Linear Field Transducer panels

|

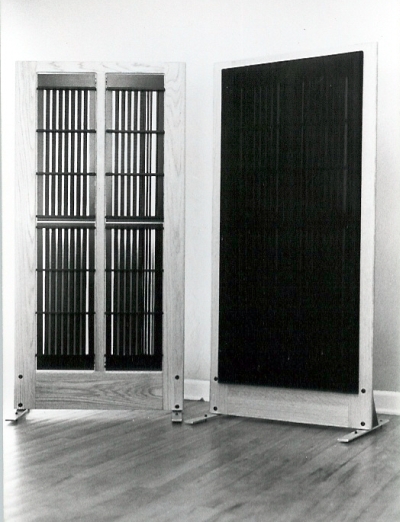

Eminent's first speaker products were push pull planar magnetic loudspeaker models LFT-3 & LFT-4. The LFT-3 was the first full range push pull planar magnetic speaker system. These were large 30" by 60" by 1" flat speakers using ceramic 8 permanent magnets and stretched polyester diaphragms. Dipole loudspeakers have difficulty playing bass because of the acoustic short circuit inherent in the design. Also planar magnetic panels of this design have restricted diaphragm displacement which limits low frequency sound output. To overcome this problem the diaphragms need to be large compared to the area of conventional cone loudspeaker mounted in a box. |

The LFT-3 Loudspeaker  |

The LFT-4 Loudspeaker  |

In order to manufacture the loudspeaker the company moved from a 2000sq ft to a 6000 square foot

building. Although rare today for a U.S. based audio company, Eminent Technology created a facility to

manufacture most of what it produces in house. Painting, welding, metal fabrication, woodworking,

woofer cabinets and planar transducers are built in house. Even the connectors on the back of the speakers,

designed by Edison Price and called Edison Price Music Post, are manufactured at Eminent. This capability

aided in the development of later products. |

|

LFT-8  |

Between 1989 and 1990 the LFT-8 three-way hybrid loudspeaker was introduced. The LFT-8 features a very low crossover frequency between the woofer and planar ribbon midrange panel. Electrically the crossover is 30Hz, acoustically it is about 180Hz. Unlike many hybrids this large overlap between the woofer and the midrange panel minimizes audibility of the crossover and allows a low coloration transition between the woofer and the mid range panel. The LFT-8's high consumer ratings, longevity and upgrade program have made it one of Eminent Technologies most successful products. |

| Planar loudspeakers utilize polyester diaphragms laminated with aluminum foil, about half the thickness of household aluminum foil. Eminent Technology's diaphragms are also manufactured in house. The conductor pattern is silk screened onto the foil with a ink resist. Then an etchant is used to remove the foil around the resist. After the ink is removed, a conductor pattern remains. The diaphragm is then tensioned in a frame and terminations are added. Once the conductors are in the presence of a magnetic field and current is supplied from an audio amplifier, the diaphragm moves following the audio signal. The disadvantage of this type of loudspeaker is efficiency and limited low frequency capability, the advantage is low distortion and transient capability. | |

The LFT-10  The LFT-10 was intoduced in 1993 as a planar car transducer to capitilize on the popularity of automotive sound systems. It met with limited success. |

The LFT-11  By 1995 the personal computer was prevalent and sound cards were included. Digital recording, games, and sound effects were transitioning to the computer. A computer multimedia speaker, the LFT-11 was created based on a modified LFT-10 for the two desktop panels with two 6.5 inch woofers in a third cabinet. This product was widely recognized by a number of audio and computer magazines as the best sounding computer multimedia speaker. |

Monsoon MM-700 Computer Speaker  |

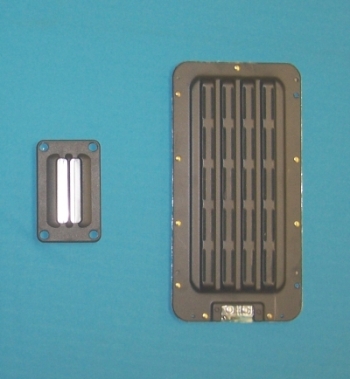

Eminent Technology had developed a still smaller transducer for a lower cost computer speaker. The smaller transducer was licensed to Sonigistix Corporation in Vancouver Canada. Sonigistix and Eminent Technology co developed home and computer products based on flat panel loudspeakers manufactured in Canada. These products carried the Monsoon brand. A smaller planar ribbon tweeter was created at Sonigistix and is used in Philips Consumer Electronics home theater in a box and other loudspeaker products. The tweeters are manufactured in China. Both the planar ribbon panel and tweeter products have found there way into several other loudspeaker company offerings. Modified versions of the Sonigistix transducers can be found in AV123 loudspeakers as well as models from VMPS and others. |

In 2002 Sonigistix was sold to Eastern Asia Technology Company, (Eastech), and renamed Level 9 Sound Designs still in Vancouver. Shortly thereafter Level 9 was moved to China. Another spin off of Sonigistix is called Magnetic Audio Devices (MAD), designers and builders of planar magnetic transducers primarily used for professional audio applications.

Eminent/Sonigistix Transducers

|

Polycore Indonesia

Eminent Technology has also designed conventional loudspeakers for in house use and consulted on the design of cone loudspeakers for overseas manufacturers. The largest Indonesian consumer electronics manufacturer, P.T. Hartana Istana Electronics, brand names Polycore and Polytron, uses a cone speaker and cone formulation designed at Eminent Technology for televisions, radios and consumer products. |

Eminent Technology LFT-16  |

2005 - The LFT-16, a three way hybrid was designed using a modified LFT-10 and a Eastech designed planar ribbon tweeter. |

The TRW-17, In 2006 a new type of sound reproducer, the worlds first rotary woofer was introduced. It has specifications and performance capability like no other woofer on the market. It can reproduce sound from 0Hz to 20hz and is designed to fill in below the frequency range of existing subwoofers. Eminent Technology now faces the challenge of convincing the general public and engineers that we can hear below 20Hz and content exist that can be reproduced.

Eminent Technology TRW-17  |

Each decade of sound recording and reproduction brings wider and wider bandwidth. Four years in development, the rotary woofer creates sound by rotating a set of blades. Sound represents very small changes in air pressure. As the blades rotate at a constant speed, the pitch follows the signal from the audio amplifier changing the pressure of the air just as a cone loudspeaker does. The blades have no pitch when there is no audio signal. The rotation of the blades grabs the air much more effectively than a cone and can enable high sound levels with a much more efficient conversion of energy as compared to a cone woofer. The rotary woofer has acoustic output equivalent of a very large number of conventional woofers many times its size at extremely low frequencies. |

Rotary Woofer Projects

Niagra's Fury at Niagra Falls

|

Although not well understood, at low frequencies conventional cone loudspeakers have an impedance mismatch with the air. For each halving of frequency, in theory, a cone woofer must move four times as far to maintain the same output. The impedance mismatch starts where the wavelength of sound matches the dimensions of the cone, actually a fairly high frequency. The upshot is that cones are very inefficient loudspeaker transducers only converting about 1% of the electrical energy into sound. A horn loaded loudspeaker, sometimes used in professional applications is much more efficient, however they are large and impractical at very low frequencies. |

|

Because the rotary woofer is so effective at producing very low frequencies, there is another aspect of this new product which involves our understanding of hearing. It can produce sounds well below 20Hz, in fact it can produce sounds below 1Hz. Getting consumers to believe that sound reproduction has value between 1-20Hz is challenging. This product generates controversy even among audio professionals because many believe that it produces sounds we cannot hear. |

The Middle Collegiate Church,

|

We have been taught that we cannot hear sounds with a frequencies below 20Hz. This probably originated from hearing studies done by Fletcher and Munson back in 1933 which happened to stop at 20Hz. The results of this study were published in hundreds of textbooks. More recently a number of scientific studies have been completed which show that we can actually hear sounds down to a few Hertz. Eminent Technology has already conducted one double blind study demonstrating that more than 91% of the participants could hear 16Hz, 8Hz, and 4Hz tones. Conventional audio systems with cone sub woofers are usually limited to about 20Hz. Compared to our hearing, conventional loudspeakers represent a high pass filter to sound. |

Modern digital audio recording systems have no low frequency limitations. Almost 30% of Modern movie soundtracks, and even Television shows have content down to a few Hz. These sound effects are not being reproduced by conventional loudspeakers in a movie theater or a home.

Model Twenty Guitar Speaker

Eminent Technology Model Twenty  |

Rather than just projecting sound straight ahead, the model twenty offers wide dispersion. Drums, electric bass and PA systems have wide dispersion, now the audience can get the same experience with an electric or acoustic guitar. The Model Twenty has much lower distortion, less compression and wide bandwidth suitable for electric or acoustic sources, keyboards, and synthesizers. The thin form factor works at home and it's light weight allows far easier transport and set up for your next gig. |

A complete time line of in house projects by Eminent can be seen Here

Eminent Technology keeps a low profile choosing to invest in research and development. It prides itself on being able to provide parts and service for its very first product. Its products stay in production for many years and updates are offered to the owners to prevent obsolescence. Eminent Technology is privately held. We are not done yet! Thank you for your interest in our history.